years of passion and pioneering in the world of Vanilla

products use vanilla, and the scent or flavor of these can vary widely from market to market

of black vanilla beans is combined with alcohol to make 1 liter of ten-fold vanilla extract

The global favorite

Vanilla is in our DNA – we’ve been working with the Queen of Spices for over 150 years, pouring our passion and pioneering spirit into everything we do, from creating extracts to developing fragrances.

A sweet smelling history

We’ve been a trailblazer in bringing the distinctive and complex scent of vanilla to people worldwide ever since our business began in 1874

In 1874 two chemists, Wilhelm Haarmann and Ferdinand Tiemann, produced synthetic vanillin for the first time by extracting and synthesizing it from the sap of conifers. Their discovery was a world-first, a man-made version of natural vanilla that was loved across the world. At the time vanilla was already used in a number of food products, from ice cream to sweetmeats (said to be a favorite of Queen Elizabeth I). The discovery of synthetic vanillin opened up an ever-increasing market for vanilla flavors and scents, and allowed perfumers to use it more and more in the world of fragrance.

Today, we produce over 4,400 tons of vanilla flavors and extracts every year. We blend our expertise in both the extraction of natural vanilla and the creation of synthetic and nature-identical vanillin to meet the growing demands of our global customers and consumers. From our perfumers who work closely with customers to create new scent solutions, to our experts who work hand-in-hand with farmers in Madagascar, everything we do is focused on bringing the unmistakable scent of this global favorite to people worldwide.

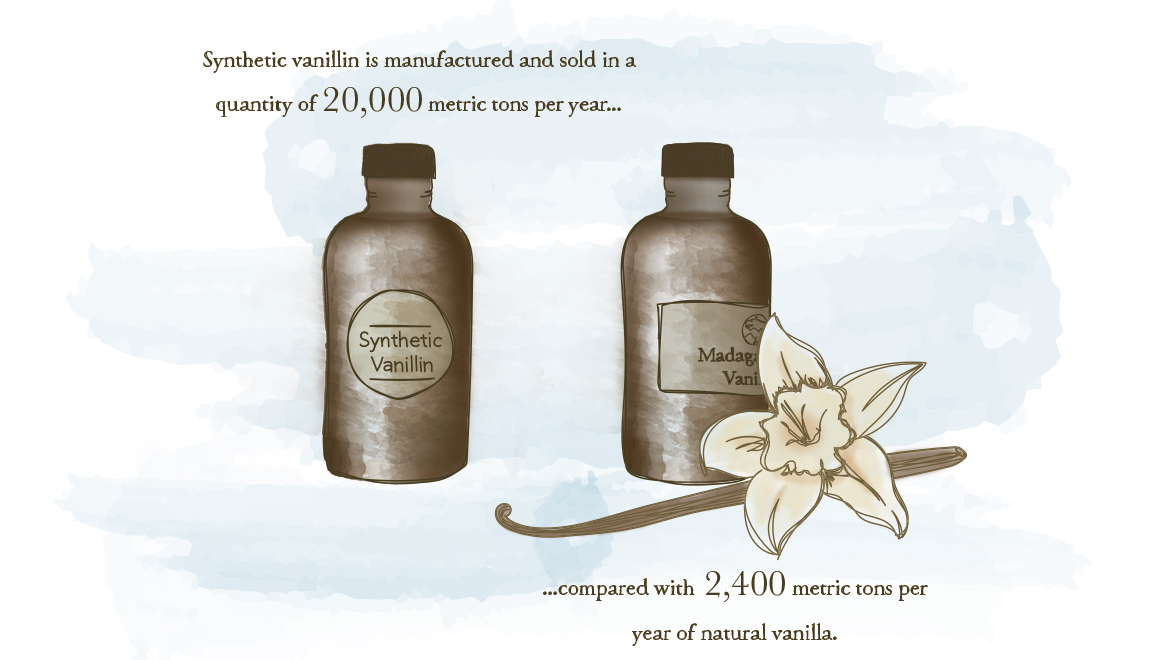

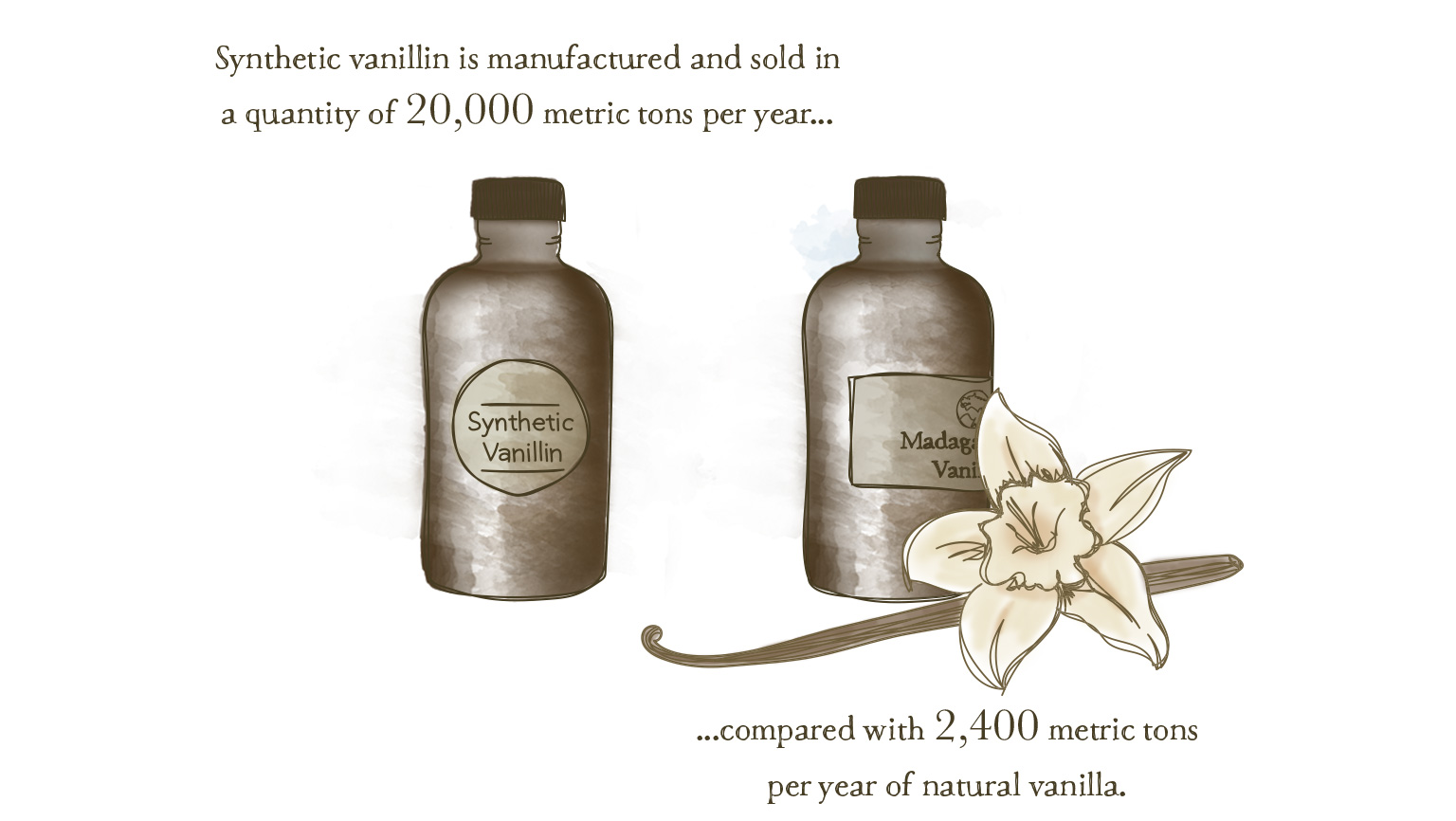

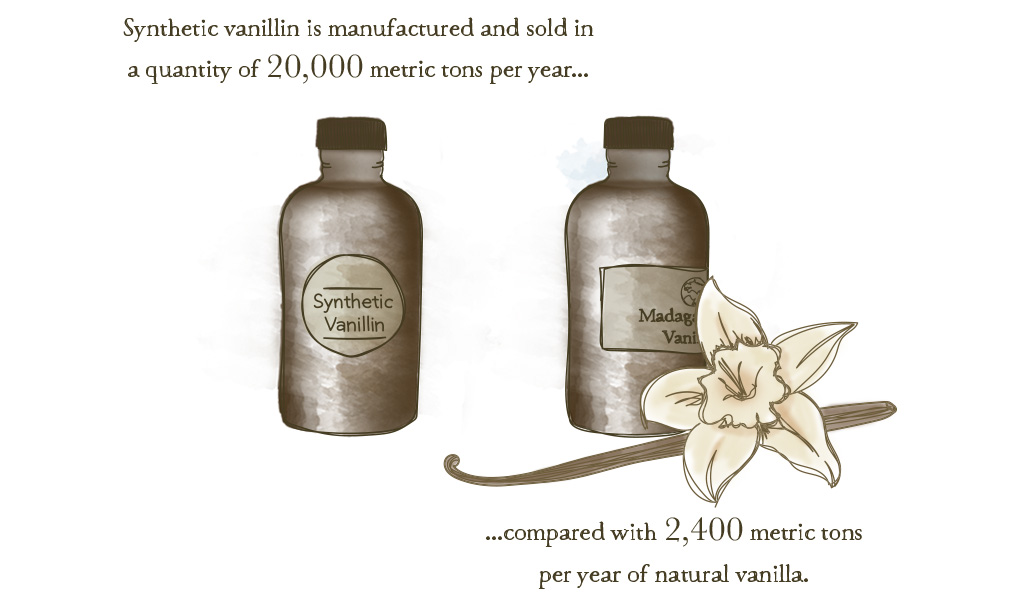

The global desire for vanilla continues to increase each year, with demand for natural vanilla regularly exceeding supply. Our ability to produce synthetic and natural vanillin is essential when it comes to meeting the needs of global customers and consumers.

Meeting increasing demands

The demand for vanilla far exceeds the supply of natural vanilla, which is why synthetic and natural vanillin are so important; they mean more and more people can enjoy the vanilla aromas they love in an ever-increasing range of products.

While scents can trigger emotional, instinctive reactions, it takes a whole lot of scientific understanding and expertise to ensure that what it is we’re smelling hits just the right note. That’s where our chemists come in.

Creating perfect smelling extracts from our natural bourbon vanilla is just one of the challenges facing our chemists. To meet the ever-increasing global demand for vanilla scents, our ability to create a range of vanilla extracts and to replicate natural products is vital. Dr Benoît Join, a Laboratory Manager, is leading teams doing just that.

“The extraction principle is traditional,” says Dr Benoît Join. “It’s been around since the 17th century and the development of modern perfumery, and it’s not really changed significantly since. That said, there is always something new to consider.”

Every step of the extraction process impacts the final product, taking some molecules away and leaving others behind. It’s all about getting that balance just right so you can create an extract that meets the customer’s needs.

“One of the most interesting things for me was seeing the new extraction facility we have in Madagascar. We’ve maintained our extraction standards there – everything operates as it would here. I also loved discovering new things. I’m currently working a lot with vetiver, so it was great to see how this crop is helping the vanilla farmers we work with, bringing them another source of income and some stability.”

Creating perfect smelling extracts from our natural bourbon vanilla is just one of the challenges facing our chemists. To meet the ever-increasing global demand for vanilla scents, our ability to create a range of vanilla extracts and to replicate natural products is vital. Dr Benoît Join, a Laboratory Manager, is leading teams doing just that.

“The extraction principle is traditional,” says Dr Benoît Join, standing in his large chemical laboratory while his team is busy carrying out this classical process on some fresh bourbon vanilla from Madagascar. “It’s been around since the 17th century and the development of modern perfumery, and it’s not really changed significantly since. That said, there is always something new to consider. Extraction can be done with water, alcohol and even CO2, and each method will bring something different to the final extract. Which one we use depends on the brief we’re trying to fill, the market a product will be used in and so on.”

“With my team, we focus on extractions and molecule synthesis for scent and care – everything from fine fragrance to washing powder. We’re interested in both extraction and synthesis, and while natural extracts are becoming increasingly sought-after, there are also considerations for our customers around cost, so there’s always a balance to find.”

“Also, when it comes to natural extracts, and particularly with vanilla, you are talking about a limited availability. There is only so much vanilla that is produced every year across the world, and that amount falls far short of the global demand for vanilla scents. One of the great things about synthetic vanillin is that is can be done on demand. It’s filling a need and a demand that we just wouldn’t be able to meet with natural vanilla extracts alone, so it’s really important that we’re always working to create the best synthetic vanillin we can.”

“Both synthetic vanillin and natural vanilla extracts are used in perfume. One of the things about natural vanillin is that it’s never 100% pure. Every impurity contributes to the uniqueness of the scent, something you can’t quite replicate. It’s fun trying though. One of my main focuses here is on new molecule synthesis. I’m fascinated by natural compounds and am always looking to better understand them. We’ll isolate individual compounds, analyze their structure and then try to recreate them. It’s like Lego, where you’re trying to piece together a structure to work out why something behaves in a certain way and then replicate that effect. We have every kind of science you could want here, it’s fantastic and means we can offer our customers the best possible solutions.”

Every step of the extraction process impacts the final product, taking some molecules away and leaving others behind. It’s all about getting that balance just right so you can create an extract that meets the customer’s needs.

“I’ve also been lucky enough to travel to Madagascar twice now and see our work there first hand. There is nothing like being exposed to natural ingredients like that, where you can smell and analyze things right there and then. I was even lucky enough to see the hand pollination of the vanilla flower. It really makes you realize just how much effort and passion goes into its production, particularly when you see the difficulty of operating somewhere with limited infrastructure and no logistics. It makes you see things in a new way.”

“One of the most interesting things for me was seeing the new extraction facility we have in Madagascar. We’ve maintained our extraction standards there – everything operates as it would here. I also loved discovering new things. I’m currently working a lot with vetiver, so it was great to see how this crop is helping the vanilla farmers we work with, bringing them another source of income and some stability.”

Capturing the complex essence of natural vanilla

Edible, sweet, rummy, sensual… bourbon vanilla is a perfumer’s dream ingredient, offering endless possibilities thanks to its incredibly complex make up of over 400 different flavor and aroma components.

Vanilla has long been a favorite ingredient in the world of fine fragrance, ever since it was first used in Guerlain’s Jicky fragrance in 1889. Today, it continues to inspire our perfumers and offers endless possibilities to those who know how to work with it. Known as the Queen of Spices or Black Gold, it can be heady and indulgent, or fresh and natural, depending on the type of extract used and what it’s paired with. It’s this versatility that makes vanilla such an enduring scent, loved across the globe.

Scent has the power to evoke memories. From a favorite ice cream to the smell of freshly baked cake, vanilla is a perennial favorite in homecare products thanks to its ability to take us back to treasured moments. Almost every customer has a vanilla fragrance in their homecare product range, from air fresheners to fabric softener. Finding the exact scent that works for different products is a challenge our teams relish, giving them the opportunity to flex their creativity in creating new products with this classic scent.

Join us on the journey from customer brief to final product and discover how the creative talent and expert knowledge of our team is helping customers across the world to capture new market opportunities.

Scenting success

Creating scents that meet a customer’s brief takes more than an expert nose. Our perfumers balance their creativity with their chemical knowledge, drawing on the skills and experience of a range of teams to produce the best possible products.

Katherin Kohlmeyer’s passion for her job is infectious. “I’m inspired by everything,” says the perfumer. “Being a perfumer is like being a child in a playground. You’re always on the job, whether you’re walking through a forest or shopping in a market. I believe you have to go through the world with open eyes and an open nose. You never know where you’ll find your next great idea – it’s a never ending story.”

It’s so great to see customers enjoying fragrances and getting the feelings you want them to from something you’ve helped to create.

“Whenever I’m coming up with a new perfume formula, I’m weighting the various means of supporting the vanilla impression. How much do I need for a specific application? Should I focus on top or base notes? How will it perform at certain heats? Of course, I’m also influenced by trends, and I work very closely with our marketing and evaluation teams to understand what’s new, what consumers want and how we can translate this into scent solutions for our customers.”

Katherin Kohlmeyer’s passion for her job is infectious. “I’m inspired by everything,” says the perfumer. “Being a perfumer is like being a child in a playground. You’re always on the job, whether you’re walking through a forest or shopping in a market. I believe you have to go through the world with open eyes and an open nose. You never know where you’ll find your next great idea – it’s a never ending story.”

With a background in chemistry, Katherin has over 12 years’ experience working in scent and care. “I worked as a lab technician at Symrise in the application area,” she explains. “When the perfumery school opened here in Holzminden, I enrolled the first year it was open. Ever since I started here I’ve been fascinated by the work done by the perfumers; I love the idea of creating something that people want to have in their homes. But I think my background in chemistry really helps me as a perfumer too. Understanding how things like the evaporation process, molecular weight and the stability of raw materials will impact a final product means I can create the best scent solutions possible for our customers.”

“This is really important with vanilla. I work a lot in air care (candles, reed diffusers, air fresheners etc.), and because vanilla is crystalline, it can present a whole range of challenges. It doesn’t like to evaporate so in something like a reed diffuser you can end up with crystals forming on the reeds. You also can’t use it in membrane technology because the crystals are just too big. This is where our expertise at Symrise comes in. If we have a client brief that asks for a vanilla scent in a membrane product, we need to use alternative materials and ingredients to create the impression of vanilla.”

“Different products present different challenges. For reed diffusers, top notes are really important and you have to consider that all the perfume oils need to travel through the sticks and then evaporate, ideally over six to eight weeks. But then in something like a fabric softener, base notes are key because you want that long lasting scent, so when a consumer takes their washing out of their cupboard they still get that hit of fresh scent. Vanilla is ideal for this, thanks to its bigger molecules.”

“Whenever I’m coming up with a new perfume formula, I’m weighting the various means of supporting the vanilla impression. How much do I need for a specific application? Should I focus on top or base notes? How will it perform at certain heats? Of course, I’m also influenced by trends, and I work very closely with our marketing and evaluation teams to understand what’s new, what consumers want and how we can translate this into scent solutions for our customers.”

It’s so great to see customers enjoying fragrances and getting the feelings you want them to from something you’ve helped to create.

“One of the big trends at the moment is for gourmand scents, and vanilla is really important for this. While gourmand scents are particularly popular in Europe and the US, I tend to find that scent trends are as much influenced by the seasons as they are by regions. For example, around Christmas time, we get a lot of customer briefs for edible scents. Once we have a brief, we’ll look at a customer’s existing range with our marketing teams, and try to identify gaps, or if they have a signature style. I’ll also work with the application teams to get specific insight into raw materials. Once I have all the information I need, I’ll create a formula for the scent. Really it’s like baking, like creating a recipe.”

“Once I have the recipe, I send it to our compounding machine and I can be testing a sample within as little as 24 hours. Testing is really important as every product you create is different – the same materials can give different impressions, different client bases can react in different ways and so on. That’s true even of a classic like vanilla that we use more or less everywhere in the homecare world.”

Perfect products need more than the best raw ingredients: skill and understanding are what take those building blocks and transforms them into successful, tailor-made scent solutions.

When it comes to creating homecare products consumers love, there’s more to success than smell. The burn time on a candle, how long a scent lasts on our freshly washed clothes or the way it diffuses over time all impact how we feel about a product. Finding the perfect balance is what our applied research teams do every day.

“I spend a lot of my time in labs like this one, although you’re just as likely to find me scrutinizing a spreadsheet,” laughs Astrid Kaufhold, Head of Application Lab for Homecare, EMEA. “Over my years in this business I’ve worked in several application labs so I feel at home in the lab, but as the head of this department now, one of the most important things I do is coordinate sample requests and deliver for internal and external customers in time.”

One of the best things about my job is that no two days are the same because everything is always changing. From consumer trends to what our customers want, I love the challenge of finding better ways of doing something.

“Of course, one of the big challenges with my work is that things are always changing. There are always new trends and new ideas to be explored. Only a few years ago, the majority of products were cloudy – today that’s changed, and consumers want clear products. This is a trend that has come from the personal care market, and it presents a new challenge. We work closely with the marketing and evaluation teams to identify trends like this before our customers ask for them. This means that we have often already worked on and tested a particular idea before we see it in a brief, although of course, we’re also always learning from our customers too. The challenges are what make me love my job – there is always something new to try.”

When it comes to creating homecare products that consumers love, there’s more to success than the way a product smells. The burn time on a candle, how long a scent lasts on our freshly washed clothes or the way a scent diffuses over time all impact how we feel about a product. Finding the perfect balance between all the factors that go into making a successful product is what our applied research teams do every day.

“I spend a lot of my time in labs like this one, although you’re just as likely to find me scrutinizing a spreadsheet,” laughs Astrid Kaufhold, Head of Application Lab for Homecare, EMEA. “Over my years in this business I’ve worked in several application labs so I feel at home in the lab, but as the head of this department now, one of the most important things I do is coordinate sample requests and deliver for internal and external customers in time.”

Astrid and her team work with over 300 raw materials, and are a vital part of the work that goes into fulfilling a customer brief. “No two briefs from a customer are ever the same,” she explains. “For example, if you’re working on a new candle, the candle base for one customer will differ to another, so how a perfumer’s scent formula will perform in one won’t necessarily be the same when you apply it to another.”

“This makes the stability testing of raw materials so important. We’re able to work with perfumers to help them understand how certain molecules will perform in different conditions; how they react to heat or moisture; how they impact the burn time of a candle, or if they will increase the diffusion effect of a scent and so on. We keep a database of all the raw materials we use which is accessible by all our colleagues across the world. This means no matter where a customer is based, we already have vital knowledge about the raw ingredients they may want to use in their new product that we can draw on and use to inform the product development. It means we’re never starting from scratch.”

One of the best things about my job is that no two days are the same because everything is always changing. From consumer trends to what our customers want, I love the challenge of finding better ways of doing something.

“One of the other major benefits of this is that it helps us react quickly to customer briefs; sometimes the turnaround time can be as little as two months. First, a brief will be assessed by our marketing, evaluation and sales teams, who will look at a customer’s existing products, trends, regulatory requirements and so on. Then the perfumers will create an idea and formula which will be compounded, and then it’s up to us in the application lab to incorporate this into a product that will work in the chosen market. The tight time frames mean that we need to be as close to perfect as possible first time around – our customers don’t have time to take a product through several iterations. Knowing how raw materials will perform helps us achieve this.”

“Of course, one of the big challenges with my work is that things are always changing. There are always new trends and new ideas to be explored. Only a few years ago, the majority of products were cloudy – today that’s changed, and consumers want clear products. This is a trend that has come from the personal care market, and it presents a new challenge. We work closely with the marketing and evaluation teams to identify trends like this before our customers ask for them. This means that we have often already worked on and tested a particular idea before we see it in a brief, although of course, we’re also always learning from our customers too. The challenges are what make me love my job – there is always something new to try.”

Vanilla is an evocative scent, loved worldwide. We’re committed to ensuring that this remains the case, and that we can continue to deliver scent solutions that delight consumers and customers everywhere.

Vanilla is like fine wine – it gets better with age. We’ve been working with vanilla for more than 150 years, and our passion for this Queen of Spices is as strong as ever. The fact that vanilla is so universally popular, and that it touches every area of scent and care, means vanilla will continue to play a key role in the future of our business.

Everything we do with vanilla, from working with farmers in Madagascar to developing a new fragrance that places vanilla at its heart, is focused on honoring the Queen of Spices, vanilla, and all its subtle, complex and timeless qualities.